Scaffolding will be used in the construction of the steel structure workshop. Here is how to build scaffolding.

The structure of the longitudinal horizontal rod shall meet the following requirements:

1. The longitudinal horizontal rod should be set on the inside of the vertical rod, and its length should not be less than 3 spans;

2. Longitudinal horizontal rod joints should be connected by butt fasteners or lap joints. Butt joint and lap joint shall meet the following requirements:

(1) The butt fasteners of longitudinal horizontal rods should be staggered: the joints of two adjacent longitudinal horizontal rods should not be set in synchronous or same span; the distance of two adjacent joints that are not synchronized or different spans should be staggered in the horizontal direction should not be Less than 500mm; the distance from the center of each joint to the nearest main node should not be greater than 1/3 of the longitudinal distance.

(2) The lap length should not be less than lm. Three rotating fasteners should be set at equal intervals to fix it. The distance from the edge of the end fastener cover plate to the lap longitudinal horizontal rod end should not be less than 100mm.

The structure of the horizontal horizontal rod shall meet the following requirements:

1. A horizontal horizontal rod must be installed at the main node, which is fastened with right-angle fasteners and disassembly is strictly prohibited. The center distance between the two right-angle fasteners at the main node should not be greater than ± 50mm. In double-row scaffolding, the external elongation of the end against the wall should not be greater than 0.4L and should not be greater than 500mm.

2. The horizontal horizontal rods at the non-main nodes on the working layer should be set at equal intervals according to the needs of supporting scaffolding, and the maximum spacing should not be greater than l/2 of the longitudinal distance.

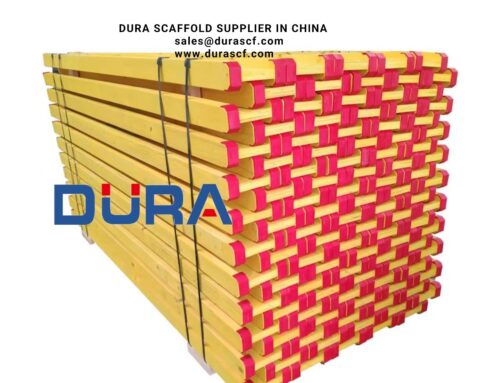

3. When using wooden scaffolding, both ends of the horizontal horizontal rods of the double-row scaffolding should be fixed on the vertical horizontal rods with right-angle fasteners.

The setting of the scaffolding shall meet the following requirements:

1. The working floor scaffolding should be covered and stabilised, 120~150mm away from the wall;

2. The wooden scaffolding should be set on three horizontal horizontal rods. When the length of the scaffolding is less than 2m, it can be supported by two horizontal horizontal rods, but the two ends of the scaffolding should be reliably fixed with it to prevent tipping. The scaffolding can be paved with butt joint tiling or lap joint. When the scaffolding board is tiled, two horizontal horizontal rods must be set at the joint. The external extension of the scaffolding board should be 130-150mm. The sum of the external extensions of the two scaffolding boards should not be greater than 300mm. When the scaffolding board is laid together, the joint It must be supported on a horizontal horizontal rod, the lap length should be greater than 200mm, and the length of its extending horizontal rod should not be less than 100mm.

3. The length of the scaffold board probe at the end of the working layer should be 150mm, and both ends of the board length should be reliably fixed with the support rod.

Upright

1. The base or pad should be set at the bottom of each pole.

2. The scaffolding must be equipped with vertical and horizontal sweeping rods. The vertical sweeping pole shall be fixed on the pole at a distance no greater than 200Em from the base epithelium using right-angle fasteners. The horizontal sweeping rods should also be fixed on the uprights immediately below the longitudinal sweeping rods with right-angle fasteners.

3. The bottom step of the scaffolding should not be greater than 2m.

4. The pole must be connected to the building reliably with connecting wall pieces, and the spacing between the connecting wall pieces should be 40m2.

5. The length of the pole is connected. In addition to the top step of the top layer, lap joints can be used, and the joints of each step of the remaining layers must be connected by butt fasteners. Butt joint and lap joint shall meet the following requirements:

(1) The butt fasteners on the poles should be staggered; the two adjacent joints should not be set in the synchronization, and the distance between the two spaced joints separated by a pole in the height direction should not be less than 500mm; each joint The distance from the center to the main node should not be greater than l/3 of the step.

(2) The lap length should not be less than lm, and should be fixed by not less than 2 rotating fasteners, and the distance from the edge of the end fastener cover plate to the rod end should not be less than 100mm.

Even wall pieces

1. It should be set close to the main node, and the distance from the main node should not be greater than 300mm;

2. The installation should start from the longitudinal horizontal bar at the first step of the ground floor. When it is difficult to install at this place, other reliable measures should be adopted to fix it;

3. The diamond-shaped arrangement should be preferred, and the square and rectangular arrangement can also be adopted;

Scissors and horizontal braces

1. The double-row scaffolding shall be provided with scissors braces and lateral braces.

2. The setting of scissors support should meet the following requirements:

The number of spans of each scissor spanning the vertical pole The width of each scissor span should not be less than 4 spans, and should not be less than 4 spans, and should not be less than 6m. The inclination of the inclined rod to the ground should be between 45° and 60°.

3. For double-row scaffolds with a height of more than 24m, scissors braces shall be provided continuously on the entire length and height of the outside facade.

4. It is advisable to use lap joints for the length of the scissors brace.

5. Scissor bracing rods should be fixed to the extending end or vertical pole of the horizontal horizontal rods intersecting with the rotating fasteners. The distance from the center line of the rotating fasteners to the main node should not be greater than 150mm.

6. The facade is sealed with dense mesh.

Demolition:

l, should fully check the scaffolding fastener connection, connecting wall parts, support system, etc. whether it meets the construction requirements.

2. The person in charge of the unit’s project shall carry out the dismantling of the safety technology.

3. The debris and ground obstacles on the scaffold should be eliminated.

4. The demolition operation must be demolished layer by layer from top to bottom. It is strictly forbidden to demolish the entire layer or several layers of the wall piece before removing the scaffold; the height difference of the demolition by section should not be greater than 2 steps, if the height difference is greater than 2 steps, additional Reinforcement of even wall pieces.

5. When the scaffolding is dismantled to the height of the last long pole in the lower part (about 6.5m), the temporary throwing brace should be erected at an appropriate position for reinforcement before removing the connecting wall pieces.

6. When the scaffolding is dismantled in sections and on separate surfaces, the two ends of the scaffold that are not to be dismantled shall be provided with connecting wall pieces and transverse diagonal bracing for reinforcement according to the specifications.

Leave A Comment